Contact a Sales Rep

Our apologies...

An error has occurred while submitting. Please try again later...

Thank you!

Your form was submitted successfully

3M™ Flexible Pad Conditioner bristles can be tuned to the hardness and structure of your pad, including a broad range of options tested for compatibility with common pads and processes.

3M™ Flexible Pad Conditioner is a transformative solution for the unique challenges of conditioning and texturing CMP pads. With this solution, 3M has combined the quick pad break-in time and powerful conditioning performance of diamond pad conditioners with the effective defect performance of brushes. Constructed of a durable unibody polymer, this flexible pad conditioner pushes beyond the limits of traditional diamond pad conditioning to help enable a new level of customization and performance, featuring tunable design, long lifespan and the potential to help reduce defects.

In addition to powerful pad conditioning, 3M™ Flexible Pad Conditioner is also highly effective in pad cleaning applications. Because of its controlled, consistent bristles and spacing, it helps minimize trapped slurry and debris compared to conventional brushes, including for ceria, cationic silica and other difficult-to-clean slurries. The bristle material is also easier to clean with water than conventional products, and the tough unibody polymer reduces bristle loss to virtually zero.

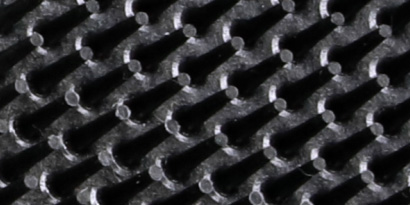

High-resolution image analysis shows that nearly all bristle tips (shown in red) will make contact with the pad surface, helping enable very consistent conditioning performance during the disk lifetime. In addition, the tightly controlled manufacturing process helps keep disk-to-disk variability in working bristle tips to a minimum.

You can customize many of the key performance properties, including:

• Bristle tip diameter

• Bristle length

• Bristle base diameter

• Bristle hardness (tailorable within a broad range)

• Carrier material (stainless steel or ceramic)

An error has occurred while submitting. Please try again later...

Your form was submitted successfully

Current product  3M™ Flexible Pad Conditioner 3M™ Flexible Pad Conditioner | ||||

|---|---|---|---|---|

| Abrasive Material | Nylon Fibers | |||

| Application | CMP, Advanced Node (Memory & Logic), Wafer Manufacturing | |||

| Brands | 3M™ | |||

| Product Type | Pad Conditioner |