3M™ Trizact™ Cloth Belt 463FC

- | Select product options for IDs.

Details

Highlights

- Designed for centerless, cylindrical and flat finishing applications

- Engineered silicon carbide abrasive grain cuts fast for high throughput

- Tough, durable YF-weight cloth withstands rugged use on tough metals

- Waterproof backing allows wet grinding and finishing

- Well suited for metals including zirconium, titanium, carbon steel, stainless steel and other alloys

3M™ Trizact™ Cloth Belt 463FC is designed with an engineered silicon carbide grain resin-bonded to a waterproof, durable YF-weight cloth backing. This belt is made for operations run with coolant when finishing and polishing carbon steel, stainless steel, nickel alloys, zirconium and titanium parts.

Engineered silicon carbide abrasive grain cuts fast for high throughput

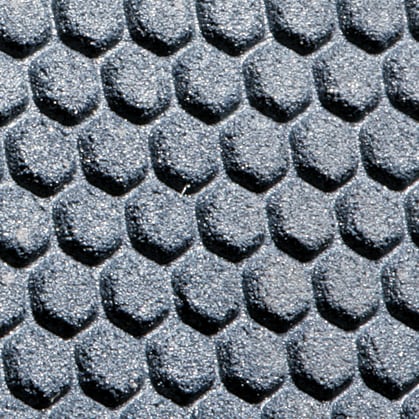

Commonly used for final finishing and polishing of cylindrical and flat metal parts, our 3M™ Trizact™ Cloth Belt 463FC is easily distinguished by the distinctive hexagonal mineral pattern on its surface.

To achieve precise surface parameters, the size, shape and surface of the abrasive mineral is key to success. Irregular mineral size and shape can scratch or gouge and perform less reliably. That's why we constructed this belt with Trizact silicon carbide mineral. 3M Trizact belts feature an engineered surface of three-dimensional composite structures. As these structures wear, fresh mineral is delivered constantly and evenly to the work surface, so cut and finish remain consistent and predictable throughout the life of the belt.

A durable YF-weight polyester cloth backing is made for operations run with coolant. Coolants serve to clean away debris and maintain work quality, stabilize part dimensions and to extend abrasive life.

Sharp Mineral for a Smooth Finish

Silicon carbide is a sharp, narrow and hard abrasive grain that fractures easily. The benefit of this "friability" is that freshly sharp edges are continuously exposed to the work surface. This grain penetrates challenging metals and cuts faster under light pressure to meet geometrical and quality specifications.

For final finishing and polishing of rod, tube and pipe for nuclear energy, aerospace, hydraulic components, automotive components, medical, industrial equipment, this belt is available in micron-graded A45, A20, A10 and A6 in a variety of made-to-order forms. Belts wider than 25" require multiple splices.

Typical properties

| Abrasive Material | Silicon Carbide |

| Backing Material | Cloth |

| Backing Weight | YF Weight |

| Bond Type | Resin |

| Brands | Trizact™ |

| Micron Grade | A20, A30, A45 |

| Product Form | Belt |

For industrial/occupational use only. Not for consumer sale or use.

3M industrial and occupational products are intended, labeled, and packaged for sale to trained industrial and occupational customers for workplace use. Unless specifically stated otherwise on the applicable product packaging or literature, these products are not intended, labeled, or packaged for sale to or use by consumers (e.g., for home, personal, primary or secondary school, recreational/sporting, or other uses not described in the applicable product packaging or literature), and must be selected and used in compliance with applicable health and safety regulations and standards (e.g., U.S. OSHA, ANSI), as well as all product literature, user instructions, warnings, and other limitations, and the user must take any action required under any recall, field action, or other product use notice. Misuse of 3M industrial and occupational products may result in injury, sickness, death, or property damage. For help with product selection and use, consult your on-site safety professional, industrial hygienist, or other subject matter expert.

3M™ Trizact™ Cloth Belt 463FC

3M™ Trizact™ Cloth Belt 463FC 3M™ Trizact™ Cloth Belt 953FA

3M™ Trizact™ Cloth Belt 953FA 3M™ Trizact™ Cloth Belt 363FC

3M™ Trizact™ Cloth Belt 363FC