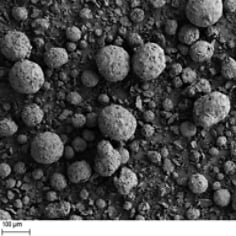

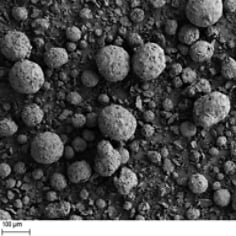

3M™ Boron Nitride Cooling Filler Agglomerates

3M Stock

B5005473000

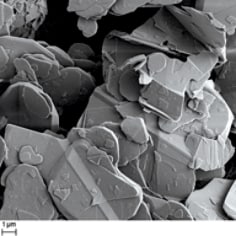

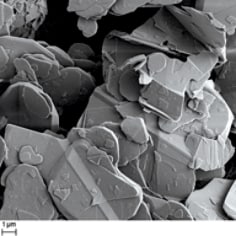

3M™ Boron Nitride Cooling Filler Platelets

3M Stock

B5005473002

3M™ Boron Nitride Cooling Fillers do much more than just add thermal conductivity to resin systems. Meeting the increasing need for “smart” polymers, especially in electrified vehicles, 3M BN cooling fillers are helping enable a new generation of electrical and electronic components in automotive production.

This versatile family of ceramic fillers can functionally integrate thermal management into polymers, without affecting electrical insulation. The result is higher performing components and materials that can be used in more places in the vehicle. The possibilities are just beginning.

Learn how Raschig GmbH, a manufacturer of special plastics, worked with 3M to create epoxy resin-based thermoset compounds for direct injection overmolding (DIM) – a process that can encapsulate and protect sensitive electronic components and reduce assembly steps in automotive applications. Using 3M BN cooling fillers, thermoplastics meeting requirements for thermal conductivity, electrical insulation linear expansion as well as injection mold temperatures and cavity pressures.

Thermal conductivity

With a material thermal conductivity of 400 w/mK in plane, 3M BN CF is 8-20x more thermally conductive than alumina fillers (intrinsic) and 2-8x more thermally conductive when mixed in polymers.

Electrical insulation

3M BN cooling fillers provide >10¹⁵ Ohm*cm electrical resistivity with a high breakdown strength – ideal for materials such as thin insulation foils.

Loss factor

As signal transmissions and frequencies increase, so does the risk of signal loss. 3M BN cooling fillers can help keep or improve dielectric properties with a low loss factor (Df) of 0.00035 @1GHz and permittivity (Dk) of 4 @1 GHz. *Not for specification purposes.

Processability

As 3M BN cooling fillers are among the least abrasive fillers used in plastic compounds, they can help minimize equipment wear and may help extend equipment life. They are available in multiple grades for excellent viscosity control.

Lightweight

3M BN cooling fillers have a low (2.25 g/cm³ density) which allows for boosting of compound properties while keeping the density at 1.2 – 1.6 g/cm³.

Demand for heat removal across the vehicle is growing as the performance demands on electronic components increases and as powertrains become more electrified. 3M BN cooling fillers can help by increasing the thermal conductivity of polymers such as silicones, epoxies and thermoplastics used to manage heat. These thermally conductive materials include potting resins, heat spreaders, glues, greases and insulation foils, as well as thermal interface material (TIM) foils and pads. 3M BN cooling fillers are also for injection molded thermoplastics used for housings and sockets.

An error has occurred while submitting. Please try again later...

Your form was submitted successfully

Filter

3M™ Boron Nitride Cooling Filler Agglomerates

3M Stock

B5005473000

3M™ Boron Nitride Cooling Filler Platelets

3M Stock

B5005473002