3M™ Boron Nitride Cooling Filler Platelets

3M Stock

B5005473002

3M™ Boron Nitride Cooling Filler Agglomerates

3M Stock

B5005473000

3M™ Boron Nitride Cooling Fillers (3M BN cooling fillers) increase the thermal conductivity of resin compound formulas. Even in small quantities, 3M BN cooling fillers can increase the thermal conductivity of finished components by 50 to 100%. But that’s just the start. 3M BN cooling fillers are also electrically insulating. They can withstand the pressures and temperatures of injection molding. And, because they can be added without significantly altering volume loadings, they can boost the thermal conductivity of existing compounds, help reduce filler usage and potentially lower compound costs. These capabilities mean much more than just thermal efficiency. They enable much broader uses for plastic resin-based parts – and ideal solutions for industries such as communications infrastructure and automotive OEM where light weight, electrical insulation and controlled viscosity are important.

3M BN cooling fillers can be used for :

With a material thermal conductivity of 400 W/m·K in plane, 3M BN cooling fillers can boost the thermal conductivity of polymers by 2-8x compared to alumina fillers.

3M BN cooling fillers provide >10¹⁵ Ohm·cm electrical resistivity with a high breakdown strength.

As 3M BN cooling fillers are among the least abrasive fillers used in plastic compounds, they can help minimize equipment wear and may help extend equipment life. They are available in multiple grades for excellent viscosity control.

3M BN cooling fillers are lightweight (2.25 g/cm³ density) can enable compound densities of 1.2 – 1.6 g/cm³.

3M BN cooling fillers are compatible with many other fillers. This makes them excellent as a secondary filler to “boost” the isotropic thermal conductivity of finished materials. Consider the compound shown here, containing 40% aluminosilicate filler. Simply by reducing aluminosilicate to 30% and adding 10% of 3M BN CF, the thermal conductivity of the compound goes up by 50-100% - without altering overall filler volume loadings and without significantly affecting other performance factors in finished parts.

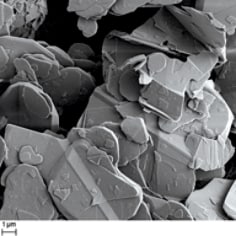

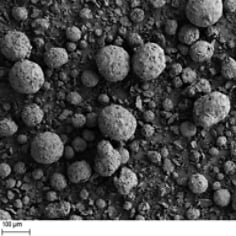

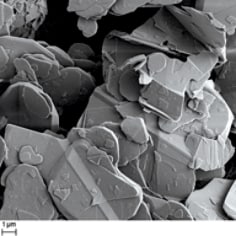

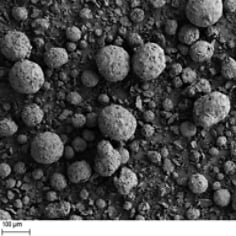

3M BN cooling fillers are available in platelets and agglomerates. Compounders can choose these types to tailor the in-plane and through-plane heat distribution of finished parts.

3M BN cooling filler platelets are excellent for higher in-plane thermal conductivity. They create relatively simple, direct heat paths that spread heat across the plane surface.

3M BN cooling filler agglomerates deliver very high through-plane conductivity to compounds and parts. They contain platelets which are randomly oriented, creating isotropic thermal conductivity within the polymer for excellent heat dissipation.

Learn about the types, grades and uses for the entire portfolio.

Exploring 3M™ Boron Nitride Cooling Fillers for TIM and CCL Applications (PDF, 1.21 MB)

Learn more about Copper Clad Laminates (CCLs) and Thermal Interface Materials (TIMs), their roles in electronic applications, and how 3M™ Boron Nitride Cooling Fillers can enhance their performance.

View and download guides for using 3M BN cooling fillers for extrusions, injection molding and more.

3M BN cooling fillers have allowed manufacturers to produce cost-saving, performance-enhancing components using thermally-conductive plastics and potting resins.

An error has occurred while submitting. Please try again later...

Your form was submitted successfully

Filter

3M™ Boron Nitride Cooling Filler Platelets

3M Stock

B5005473002

3M™ Boron Nitride Cooling Filler Agglomerates

3M Stock

B5005473000