3M™ Structural Adhesive Tape SAT1100S

- 3M Product Number SAT1100S

- 3M ID B5005408000

Details

Highlights

- Supports lightweighting compared to mechanical fastening processes

- Offers galvanic isolation for use in multi-material bonding

- Provides a cleaner and simpler application than liquid adhesives

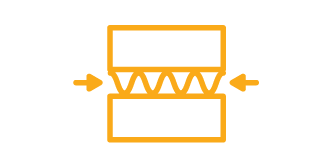

- Expansion properties offer additional simultaneous bonding and sealing

- Reduces risk of galvanic corrosion

- Provides high-bond strength to variety of materials including oily steel, aluminum, dry lubes and composites

- Precise and reliable application without squeeze-out

- Compatible with various dry lubes and stamping oils

3M™ Structural Adhesive Tape SAT1100S is a single-layer epoxy based adhesive tape formulated for metal bonding applications within body-in-white automotive manufacturing processes. This adhesive for metal-to-metal offers structural bonding strength and isolation properties to help prevent galvanic corrosion between dissimilar materials in the primary structure and vehicle closure applications. In addition to excellent bonding performance, 3M Structural Adhesive Tape SAT1100S offers sealing and gap filling properties due to its ability to expand upon application, while its precise application gives manufacturers a cleaner and simpler process compared to liquid adhesives. The structural tape is applied during body in white processing and can even be pre-applied to the part from the tier supplier. 3M Structural Adhesive Tape SAT1100S is offered in either die-cuts or in levelwound rolls.

-

Bond

Bond

Durability -

Galvanic Corrosion Prevention

Galvanic Corrosion Prevention -

Sealing and

Sealing and

Gap Filling -

Supports

Supports

Lightweighting

Easy and reliable to apply, 3M™ Structural Adhesive Tape SAT1100S offers a simpler application process compared to liquid adhesives and are compatible with a variety of surfaces – helping to support a faster and cleaner assembly process.

-

How it’s applied

How it’s appliedThis structural tape is applied during the body-in-white process and can even be pre-applied to the part from the Tier supplier. After the BiW assembly, the tape cures in an e-coat oven to achieve structural strength.

-

Customized to your specs

Customized to your specs3M Structural Adhesive Tape SAT1100S can be ordered as a levelwound roll or customized in die-cuts to fit the shape of a specific part in your assembly. 3M engineering representatives are available to help offer support for your applications.

The 3M Structural Adhesive Tape SAT1100S is constructed of rubber-toughened epoxy tape with a scrim, with liners made of transparent red polyester and a thin protective polyethylene upper layer when ordered as levelwound rolls.

Typical properties

Resources

Similar products

Current product  3M™ Structural Adhesive Tape SAT1100S 3M™ Structural Adhesive Tape SAT1100S | |||

|---|---|---|---|

| Adhesive Type | Epoxy Film Adhesive | ||

| Application | Body-in-White, Lightweighting | ||

| Brands | 3M™ | ||

| Curing Temperature (Celsius) | 180 ℃ | ||

| Curing Temperature (Fahrenheit) | 356 ℉ | ||

| Density | 1.3 g/cc | ||

| Maximum Cure Conditions (Celsius) | 195 ℃ | ||

| Maximum Cure Conditions (Fahrenheit) | 383 ℉ | ||

| Minimum Cure Conditions (Celsius) | 165 ℃ | ||

| Minimum Cure Conditions (Fahrenheit) | 329 ℉ | ||

| Product Color | Gray | ||

| Product Usage | Dissimilar Materials, Hem Flanges, Body Brackets, Chassis Components | ||

| Shelf Life | 6 Month | ||

| Storage Environment | Dry Storage | ||

| Substrate | Stainless Steel, Metal, Aluminum |

3M™ Structural Isolation Tape SIT2010

3M™ Structural Isolation Tape SIT2010