3M™ Structural Isolation Tape SIT2010

- 3M Product Number SIT2010

- 3M ID B5005286057

Details

Highlights

- Provides a durable and abrasion-resistant isolation layer between dissimilar materials

- Offers isolation between dissimilar materials to help prevent galvanic corrosion

- Customized to fit customer processes and size requirements, including die-cut parts to meet design needs

- Can cure in existing automotive bake cycles to help optimize processes

- Helps reduce time associated with material prep and cleaning due to compatibility with steel, aluminum and standard stamping/drawing lubricants

- Allows for serviceability for repairs post-assembly

- Compatible with standard stamping and drawing lubricants

- Structurally bonds to a variety of surfaces

- Can be applied to flat and non-flat surfaces, like edge wrapping and topographical surfaces

3M™ Structural Isolation Tape SIT2010 is a single-sided, die-cut tape solution designed to help prevent galvanic corrosion, offering serviceability and providing a durable and abrasion-resistant isolation layer between dissimilar materials. Optimized for current OEM and tier processes, this material is designed to bond to standard stamping/drawing lubricants without surface treatment and cure in standard e-coat and paint bake oven cycles, offering process flexibility and process efficiency.

-

Electric Isolation

Electric Isolation -

Process Optimization

Process Optimization -

Multi-Material Adhesion

Multi-Material Adhesion -

Supports Lightweighting

Supports Lightweighting

3M™ Structural Isolation Tape SIT2010 can be easily integrated into either an automated or manual manufacturing process and helps support both design flexibility and better cycle times. Its ability to bond to substrates, including non-flat surfaces, with standard stamping/drawing lubricants also helps to minimize cleaning requirements, making for a simpler process.

-

How it’s applied

How it’s applied3M Structural Isolation Tape SIT2010 is compatible with standard lubricants without surface treatment. This tape can structurally bond to a variety of substrates and surfaces and is optimized to cure in existing automotive bake cycles, eliminating the need for separate curing cycles.

-

Ready to meet your needs

Ready to meet your needsAvailable as die-cuts and other automation-ready formats to fit customer-specific application needs, 3M Structural Isolation Tape SIT2010 allows for easy application to non-flat surfaces with consistent thickness and a defined footprint of isolation.

3M Structural Isolation Tape SIT2010 is a durable, abrasion-resistant isolator that electrically insulates and conforms to substrates. It is a thermally cured epoxy structural, single-sided adhesive and cures in typical automotive cure conditions.

-

-

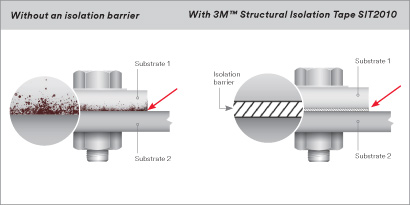

Enables protection against galvanic corrosion

Without using an isolating barrier, dissimilar materials are at greater risk for galvanic corrosion. By applying an isolating tape such as the 3M Structural Isolation Tape SIT2010, these materials can be joined effectively while offering a protective barrier between them that enables manufacturers to maintain lightweighting benefits.

Typical properties

Resources

Frequently asked questions

Designed to help prevent galvanic corrosion, 3M SIT2010 is a single-sided, die-cut tape solution offering serviceability that provides a durable and abrasion resistant isolation layer between dissimilar materials. Optimized for current OEM and tier processes, this material is designed to bond to standard stamping/drawing lubricants without surface treatment and cure in standard ecoat and paint bake oven cycles, offering process flexibility and process efficiency.

Target application segments where the isolation of dissimilar materials is required, such as: bumper, bed, body, upper-body structures, trailer, bed to frame, hinge brackets, or e-powertrain, and applications requiring ovens.

The product will be available as die-cut parts.

3M SIT2010 is a single-sided tape solution designed to provide an isolation layer between dissimilar materials. 3M SIT2010 bonds to one substrate and isolates against the second substrate. The solution structurally bonds to a variety of substrates and surfaces, including the ability to bond through standard stamping/drawing lubricants without surface treatment. Contact your regional application engineer for evaluation or testing for your specific application.

3M SIT2010 is 0.35 mm thick. Thickness information should be considered representative or typical only and should not be used for specification purposes. Product is die-cut based on the application and customer requirement.

3M SIT2010:

• Can be cured before or after part assembly, offering process flexibility

• Can be applied at the tier for final assembly for cure at the OEM, offering the potential for optimized system cost savings

• Is a single sided tape solution, allowing for serviceability and accessibility before and after OEM manufacturing

• Has the ability to be supplied in automation ready formats (such as a reel), or can be formatted for manual application, allowing process flexibility

• Bonds to metals with stamping or drawing lubes without surface treatment, reducing manufacturing costs associated with prep and cleaning

• Is optimized to cure in standard paint and ecoat bake ovens, allowing process optimization and the ability to potentially eliminate the need for separate curing cycles

• Can be cured at the tier location prior to the OEM processing

3M SIT2010 meets FAR 25.853 flammability horizontal burn test.

3M will work with you and your preferred equipment manufacturer. If you do not have a preferred equipment manufacturer, 3M can provide suggestions.

3M SIT2010 requires a thermal cure for a certain length of time at a given temperature. See the product technical data sheet for reference.

If you have an OEM application and need specification data, please contact your application engineer for support. 3M has global testing capabilities internally and works frequently with third party test organizations. 3M laboratories are IATF certified.

Similar products

Current product  3M™ Structural Isolation Tape SIT2010 3M™ Structural Isolation Tape SIT2010 | |||

|---|---|---|---|

| Application | Lightweighting, Body-in-White, Isolating | ||

| Brands | 3M™ | ||

| Maximum Cure Conditions (Celsius) | 240 ℃ | ||

| Maximum Cure Conditions (Fahrenheit) | 464 ℉ | ||

| Maximum Operating Temperature (Fahrenheit) | 176 ℉ | ||

| Minimum Cure Conditions (Celsius) | 110 ℃ | ||

| Minimum Cure Conditions (Fahrenheit) | 230 ℉ | ||

| Product Color | White | ||

| Product Usage | Dissimilar Materials, Automotive Body Structures, Chassis Components | ||

| Substrate | Metal |

3M™ Structural Adhesive Tape SAT1010

3M™ Structural Adhesive Tape SAT1010