3M™ Structural Adhesive Tape SAT1010

- 3M Product Number SAT1010

- 3M ID B40063157

Details

Highlights

- Enables dissimilar material bonding and isolation

- Excellent adhesion on steel and aluminum substrates

- Expandable structural epoxy composition provides gap filling and sealing

- Compatible with various draw and lube oils

- Comes in easy-to-apply tape formats as level-wound roll or die-cut parts

- Offers a wide range of cure or processing profiles

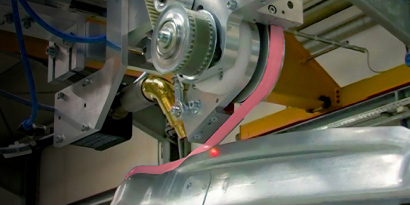

- Tape can be dispensed via automation

- Die-cut tape allows for cleaner application compared to liquid adhesives

The 3M™ Structural Adhesive Tape SAT1010 is a single-layer epoxy-based adhesive tape that provides structural bonding strength for various applications. It is an excellent option for its ability to bond dissimilar materials, allowing for the combination of new, more lightweight materials. In addition to its superior bonding performance, this structural adhesive tape features gap-filling properties due to its expansion features which can help prevent water ingress and corrosion. Easily integrated into existing manufacturing processes, this structural tape can be applied via automation for a seamless, repeatable process or is available as die-cut parts.

-

Consistent

Consistent

Thickness -

Process

Process

Optimization -

Multi-Material

Multi-Material

Adhesion -

Supports

Supports

Lightweighting

Ready-to-apply, 3M™ Structural Adhesive Tape SAT1010 rolls and die cuts allow for faster, easier and cleaner applications. No need to stress over improper mix of liquid adhesive formulations or variability in applications -- this structural adhesive tape gives you a more repeatable and predictable process.

-

How it’s applied

How it’s applied3M™ Structural Adhesive Tape SAT1010 is typically applied during the body-in-white process, where it undergoes automotive paint pre-treatment process and then the e-coat process. The tape expands and cures in the e-coat cure oven to fill and seal small gaps the hem. For typical hem designs, the tape forms a continuous barrier between both similar and dissimilar materials.

-

Customized to your specs

Customized to your specsOrder 3M™ Structural Adhesive Tape SAT1010 in levelwound rolls or customize die-cuts that match specific parts within your manufacturing process. 3M technical service representatives are available to help offer guidance for your most specific applications.

3M Structural Adhesive Tape SAT1010 is a rubber-toughened epoxy tape featuring a mesh layer that provides ease of manufacturing, a wide range of cure profiles, and compatibility with various draw and lube oils used in Body-in-White applications.

Typical properties

Resources

Frequently asked questions

3M™ Structural Adhesive Tape SAT1010M is a single layer-epoxy based adhesive tape for the Automotive industry (BIW) formulated for metal bonding applications. In addition to bonding performance the tape features gap filling properties due to expansion capabilities.

Advantages of 3M™ Structural Adhesive Tape include:

• Expandable, structural epoxy composition

• Excellent adhesion on steel and aluminum substrates

• Compatible with various draw and lube oils

• Offers a wide range of cure or processing profiles

• Stable at a controlled room temperature 21C/70F (+/-2) up to 6 months after production

• Tape can be dispensed via automation

• Cleaner application than liquid adhesives

These tapes are designed to provide structural bonding strength for various applications, specifically for bonding and isolation of dissimilar materials.

The product will be available in levelwound and as die-cut parts.

This product is intended to bond metals. For other material bonding please contact regional application engineer for evaluation or testing.

Initially, the product will only be available in the 0.2 mm and 0.4 mm thicknesses. If you have applications that require a thickness other than 0.2 mm or 0.4 mm please contact a 3M technical service representative in order to determine future thickness offerings. Levelwound rolls of the material will be available in 10 - 30 mm widths. Die-cut parts available in greater widths – up to 490 mm wide.

3M™ Structural Adhesive Tape SAT1010 provides the following advantages in the manufacturing process:

• Consistent and repeatable process with reduced manpower needs, less material and manual interference

• Simplification of process steps can lead to quality improvement

• Cleaner process than those used to apply liquid solutions

Yes, this product is spliceable. Please see the application guidelines for specific details.

The tape does not require a pre-cure process (i.e., induction or a body-in-white oven). Though, the tape can be pre-cured by induction if this is currently part of your process -- please consult with your 3M application engineer for application support.

Yes, this tape is compatible with the welding process.

Similar products

Current product  3M™ Structural Adhesive Tape SAT1010 3M™ Structural Adhesive Tape SAT1010 | |||

|---|---|---|---|

| Adhesive Type | Epoxy Film Adhesive | ||

| Application | Lightweighting, Body-in-White | ||

| Brands | 3M™ | ||

| Density | 1.1 g/cc | ||

| Maximum Cure Conditions (Celsius) | 195 ℃ | ||

| Maximum Cure Conditions (Fahrenheit) | 383 ℉ | ||

| Minimum Cure Conditions (Celsius) | 165 ℃ | ||

| Minimum Cure Conditions (Fahrenheit) | 329 ℉ | ||

| Product Color | White | ||

| Product Usage | Hem Flanges, Chassis Components, Dissimilar Materials, Body Brackets | ||

| Shelf Life | 6 Month |

3M™ Structural Isolation Tape SIT2010

3M™ Structural Isolation Tape SIT2010