3M™ Glass Bubbles K15HSN

- 3M Product Number K15HSN

- 3M ID B5005643001

3M Glass Bubbles K15HSN offer solutions for buoyancy, construction, paints and coatings.

Details

Highlights

- Help maximize positive buoyancy (lift) - achieve some of the lowest density buoyancy syntactic foams for optimal performance

- In design and construction, help enhance thermal management and improve application performance

- Help reduce resin demand and minimize raw material usage

- In exterior coatings, help provide high solar reflectance, good thermal insulation and surface protection

- Help improve energy efficiency of exterior coatings, potentially leading to lower cooling costs

- Help minimize cracking, sagging and shrinkage in adhesives, sealants and repair fillers

- In interior and exterior coatings, they provide opportunities for higher solids and lower VOC levels

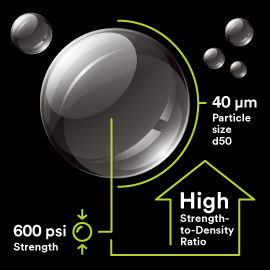

3M Glass Bubbles K15HSN are high-strength, low-density additives engineered to help improve survivability in low density applications. Featuring a density of 0.15 g/cc and a strength of 600 psi, these hollow glass microspheres are made from water-resistant, chemically stable soda-lime borosilicate glass. They help reduce density, enhance thermal insulation and contribute to energy efficiency. These versatile microspheres are used in a wide range of applications, including construction, paints and coatings, and oil and gas industries.

-

Help Maximize Positive Buoyancy (lift)

Help Maximize Positive Buoyancy (lift) -

High Survivability

High Survivability

Subsea -

Improved Surface Finish Due to Small Particle Size

Improved Surface Finish Due to Small Particle Size -

Industry-Standard Additive for Syntactic Foams

Industry-Standard Additive for Syntactic Foams

-

How 3M Glass Bubbles work

With an optimal balance of high strength and low density, 3M Glass Bubbles K15HSN help create materials that are versatile, lightweight and easy to work with in construction, paints and coatings applications, plus deep-water oil and gas buoyancy operations.

3M™ Glass Bubbles are finely dispersed, free-flowing powders consisting of thin-walled hollow glass microspheres. Made of soda-lime borosilicate glass, 3M Glass Bubbles are chemically inert, nonflammable and water resistant. Because spheres have the lowest surface area to volume ratio of any shape, 3M Glass Bubbles K15HSN pack tightly for high filler loading. Strong enough to survive processing, they can be incorporated into a wide range of polymers for density reduction. Far beyond lightweighting, the inherent properties of these microspheres provide a number of unique performance and processing advantages such as minimizing impact on viscosity and ease of incorporation.

-

3M Glass Bubbles in design and construction

3M Glass Bubbles in design and constructionHigh temperatures on roofs and exterior paints due to weather exposure and damaging infrared rays lead to increased indoor temperatures, resulting in higher cooling costs and reduced energy efficiency. 3M Glass Bubbles K15HSN in paints and coatings help enhance solar reflectance, reduce condensation, and potentially improve thermal management in applications.

3M Glass Bubbles in sealants, adhesives, and repair compounds offer lightweight solutions that help reduce sagging, cracking, and shrinkage, providing potential ergonomic benefits and enabling thicker applications. In repair compounds, they enhance the surface finish, making it smoother and paintable, while maintaining lightweight properties.

-

3M Glass Bubbles in oil and gas

3M Glass Bubbles in oil and gasThe high pressures of deepwater environments place enormous challenges on flowlines, risers and critical equipment. 3M Glass Bubbles K15HSN are the newest addition to the 3M portfolio offering with an optimal balance of high-strength and the low density of the hollow glass spheres. They can be used as an additive and help enable the net buoyancy lift for syntactic foams used in deep-sea buoyancy applications such as buoyancy models, buoys, or buoyancy blocks for remote operated vehicles.

Typical properties

Resources

Request a Sample

Our apologies...

An error has occurred while submitting. Please try again later...

Thank you!

Your form was submitted successfully

Similar products

Current product  3M™ Glass Bubbles K15HSN 3M™ Glass Bubbles K15HSN | |||

|---|---|---|---|

| Appearance (Unaided Eye) | White Powder | ||

| Application | Thermal Insulating, Viscosity Management, Buoyancy Enhancing, Lightweighting, Performance Enhancing | ||

| Brands | 3M™ | ||

| Composition | Soda-lime Borosilicate Glass | ||

| Crush Strength (Imperial) | 600 psi (80% Minimum Fractional Survival) | ||

| Crush Strength (Metric) | 4.13 MPa (80% Minimum Fractional Survival) | ||

| Product Usage | Flotation Devices, Industrial Coatings, Insulation Coatings, Dry Mortar Insulation Plaster, Emulsion Explosive Sensitizers, Caulks, Aircraft Components, Architectural Coatings, Non-Structural Adhesives, Non-structural Composites, Polymer Wood Composites, Potting Compounds, Sealants, Structural Adhesives, Lightweight Body Fillers, Lightweight Repair Compounds, Lightweight Spackle, Syntactic Foams, Thermoset Composites, Tooling Boards | ||

| Shape | Thin-walled Hollow Spheres | ||

| Typical Density | 0.15 g/cc | ||

| Typical Median Particle Diameter | 40 µm |

3M™ Glass Bubbles K20

3M™ Glass Bubbles K20 3M™ Glass Bubbles S22

3M™ Glass Bubbles S22