3M™ Dynamar™ Polymer Processing Additive FX 5912, 25 kg (55 lb) Case

- 3M Product Number FX 5912

- 3M ID 7100090858

- UPC 00051135896815

Details

Highlights

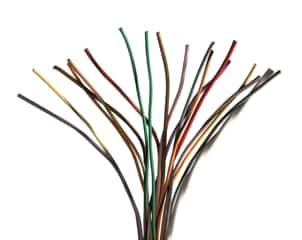

- Improves extrusion processing of polymers for wire, cable and fiber applications

- Reduces or eliminates die build-up

- Effective as a process aid over a broad process temperature range

- Broadens extrusion processing capabilities of polyolefin resins

- Excellent thermal stability

- Reduces extrusion pressure

- Reduces the transition time between color changeovers

3M™ Dynamar™ Polymer Processing Additive FX 5912 is a free-flowing fluorothermoplastic processing aid that is designed for use at very low levels to improve the processing of thermoplastics. It is designed for wire and cable applications. At designated low use levels, it will not alter or detract from the physical properties associated with high strength plastics.

Designed for wire and cable applications

- Wire and cable extrusion

- Fiber extrusion

Typical properties

| Brands | Dynamar™ |

| Container Type | Bag |

| Industries | Electrical, Packaging, Rubber and Plastic, General Manufacturing, Construction |

| Melt Flow Index (MFI) | 15-25 g/10 min. |

| Melting Point (Celsius) | 110 °C - 126 °C |

| Melting Point (Fahrenheit) | 230 °F - 258.8 °F |

| Net Weight (Imperial) | 55 lb |

| Net Weight (Metric) | 25 kg |

| Product Form | Granular, Free Flowing Granular |

| Shelf Life | 2 Year |

Resources

Data Sheets

(PDF, 76KB)

PPA FX 5912 Data Sheet

PPA FX 5912 Data Sheet